In this post, we are getting back to 3d printing basics – the terminology, and adding a bit of a twist: using Shoes to illustrate this somewhat dry and nuanced topic. Some people say “Additive Manufacturing”, others “Rapid Prototyping” and yet others “3D printing” or “Desktop manufacturing”; but are we all talking about essentially the same thing? Well, yes and no. Although the words “additive manufacturing”, “additive fabrication’, “rapid prototyping”, “desktop manufacturing”, “desktop fabrication” “3D printing”, “rapid manufacturing” have all been used interchangeably in the past, with time each is term is emerging to reflect a specific aspect of the field, and is being assigned a distinct definition.

The most common terms that are most widely used today are “additive manufacturing’, “rapid prototyping” and “3D printing”. While these words are at times used interchangeably, they actually represent different aspects of this new technology. To help put color to a somewhat dry discussion of terminology, I’ve added examples of shoes.

Additive Manufacturing

Additive manufacturing is the term with the widest reach, and is essentially defined as the manufacturing process of building an object layer by layer by ‘adding’ material. This is contrasted with the more traditional manufacturing techniques where the ‘extra’ material is removed to produce the final shape. In its very essence, people have been using ‘additive’ manufacturing processes for centuries, for example by weaving together items from plant base materials (tree bark, cane or wicker).

One of the earliest forms of footwear in the known history, “bast shoes”, were actually weaved together out of reeds, in essence using an ‘additive’ process. Making fabrics, either using a loom and weaving or felting, or knitting or crocheting is an additive process as well, as the material is made from string that is added layer by layer. Cutting out a pattern from cloth and putting together clothing, however, is a subtractive process, as the needed shape is subtracted from the whole, leaving ‘scraps’ of unused material behind.

The modern use of Additive Manufacturing is clear in that it requires a digital instruction file, and is no longer a manual process. However, the definition is still greatly applied to a ‘process’, or a consistent and systematic way of making things more than once.

In the greater community, over the past several years, the general usage of Additive Manufacturing stresses the “manufacturing” aspect and is in general used when discussing the ‘industrialized’ version of the 3D printing world. Additive Manufacturing is a term most often applied to the utilization of 3D printing technology by larger firms and corporations, for production of end-user items, on a wider and grander, more professional as well as more consistent scale, with a greater focus upon the technological aspect.

It is interesting to note that even under this more high-tech oriented definition, the Fashion Industry has already been working hard on developing Additive Manufacturing in the production of the ‘seamless garment’. 3D knitting involves a computerized circular knitting machine, and allows for mass production of a complete 3D knitted garment seamlessly using a digital file. While used for ages in production of smaller, simpler pieces, this technology has been in research stages for the past few years in developing the capacity of creating larger seamless garments in a range of textures and materials.

Interestingly, Nike has used knitting technology in manufacturing shoes, including the knitted “Flyknit” shoe. Although, arguably, the top of the shoe is created using Additive Manufacturing, the sole of the shoe is still created using traditional methods, making this more of a hybrid shoe (see below for ‘hybrid’).

So far, the shoe to fit Additive Manufacturing methods the closest has been the 3D printed shoes by Continuum Fashion.

Desktop Manufacturing

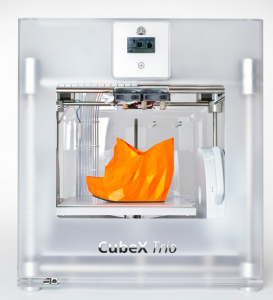

In a sense a subset of Additive Manufacturing, Desktop Manufacturing refers to the ability of producing 3D printing items right on your desktop, in a non-industrial setting. Up to date, the only shoes that I’m aware of that fit this description are the shoes recently released by 3D Systems and Cubify for printing at home using CubeX 3D printer.

Rapid Prototyping

Rapid Prototyping has been a popular way to refer to 3D printing, as for the past 20 years or so this technology has been mainly used to quickly make prototypes as a step in the greater product development and manufacture phase. It is common to think now of “Rapid Prototyping” as an application of the process of 3D printing, rather than something that functions on its own. Often the prototypes are just a step of the more traditional design and manufacture method. Although the prototype looks realistic and is therefore invaluable to help judge the final size, function and design of the piece, one only has to pick up the item to see that it is not usable as the end product: it is impossible to walk in.

Rapid Prototyping has been invaluable for the development of the best sportswear shoes on the market. Companies such as New Balance, Adidas and Nike have been using Rapid Prototyping for years to improve their designs, often resulting in better footwear and better athletic performance. Rapid prototyping also greatly increases the speed of production, with designs that once required 4-6 weeks to produce now can be finished in 48 hours.

3D Printing

The most popular term to date for this technology is 3D Printing. This term gained popularity over the past two to three years because it was easy to understand and because it has a wide reach. 3D Printing is the broadest of the three terms, unlike Additive Manufacturing, which mostly dominates in the industrial area, and unlike Rapid Prototyping, which is mostly used when referring to items created in between the production process.

Over time, 3D printing has come to apply to the process (machines and materials used for this), the application of that process (prototyping, manufacturing, end product creation, modeling), the various aspects of the industry that surrounds it (art, entertainment, jewelry, healthcare), as well as the people involve in it (engineers, designers, artists and so on).

3D Printing has been used to not only to improve the process of making a final user part, but has also been used to create the final product as well. In the fashion world, 3D printing has been used to create a number of dresses, shoes and accessories. A number of 3D printed shoes have even shown up on fashion runways, including Morphogenesis 3D Printed Shoes by Pauline Van Dongen, the ”Melonia” shoe by Naim Josefi and Souzan Youssouf, multi-material shoes by Stratasys and Iris van Herpen, and the 3D printed shoes by Pierre Renaux, as well as the “Shoes by Bryan” brand created by Bryan Oknyansky.

-

“Shoes by Bryan” split heel “Elena” -

Pierre Renaux 3D printed Shoes, close-up -

Stratasys and Iris van Herpen 3D printed multi-material shoes -

“Melonia” 3D Printed shoe -

Morphogenesis 3D Printed Shoes

test